|

|

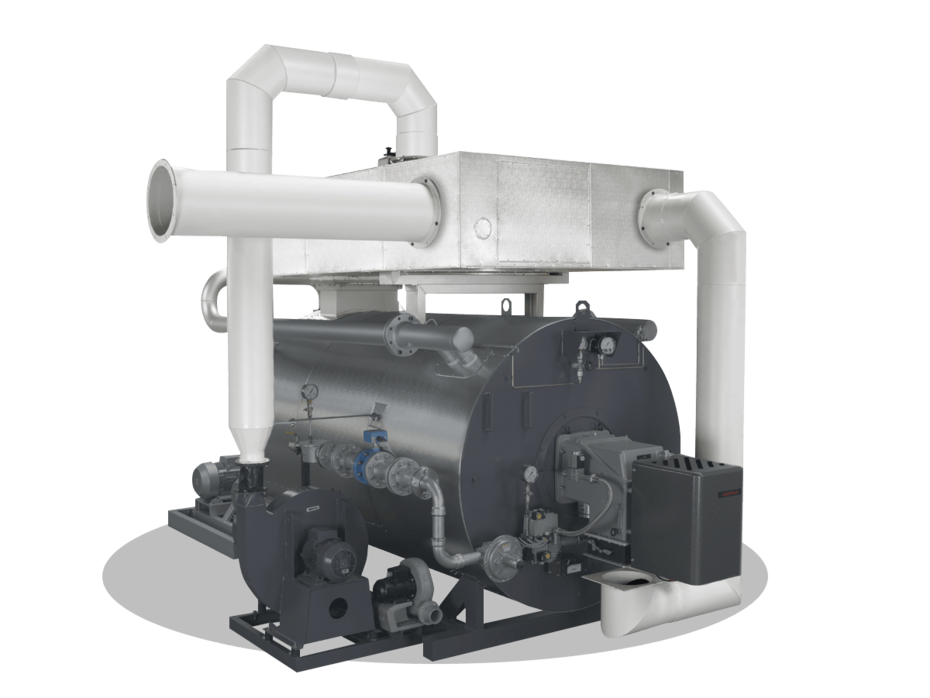

| Fires with oil, gas or solid matter up to +400 °C, from 40 to 30,000 kW. The fired plants are designed as 1-, 2- or 3-pass heaters. |

|

|

|

| New system which already realises the air pre-heating in a performance class from 300 kW. |

|

|

|

|

|

| Provides process heat up to 4,000 kW. |

|

|

|

| Almost any exhaust gas stream can be used with our energy recovery systems in order to generate valuable heat for other processes. |

|

|

|

|

|

| Uses lost heat to preheat the combustion air to maximise the efficiency of the overall plant. |

|

|

|

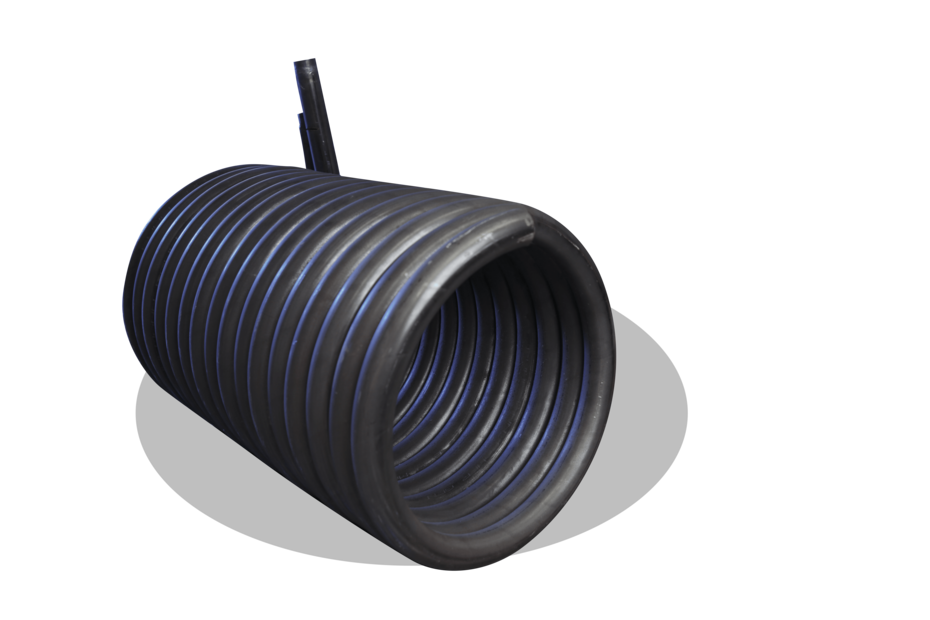

| Are used to recover heat from exhaust gas streams. |

|

|

|

|

|

| Hot and cold in perfect balance |

|

|

|

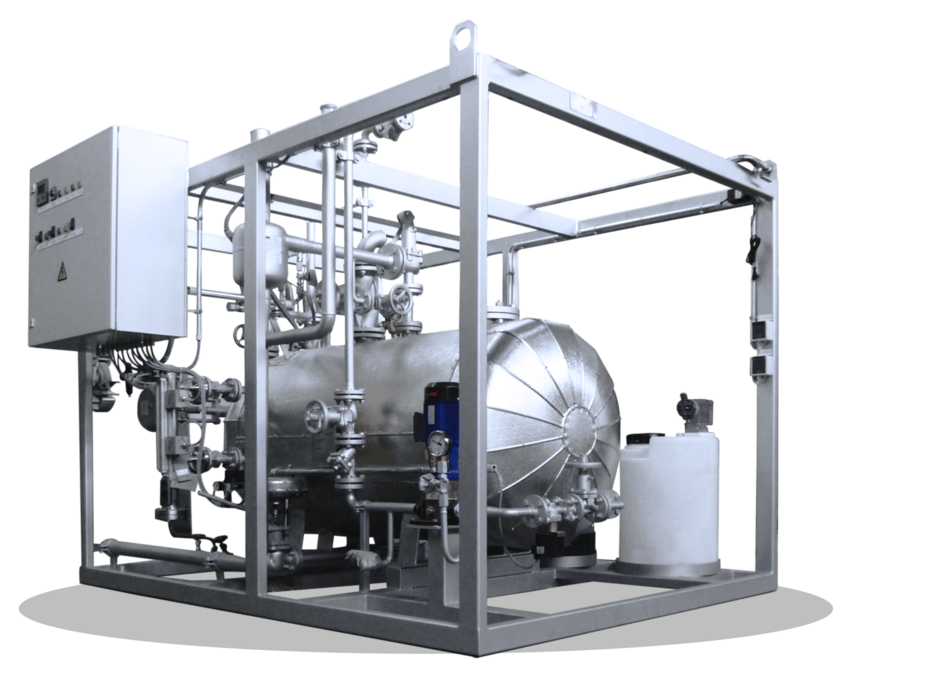

| Compact under steam, directly and indirectly heated |

|

|

|

|

| Integrated products by HTT |

|

|

|

|

|

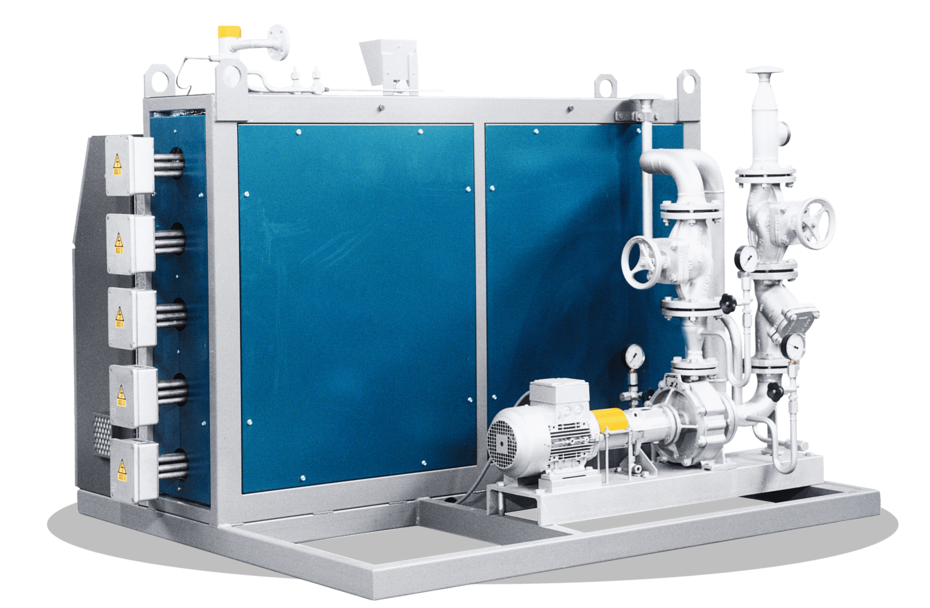

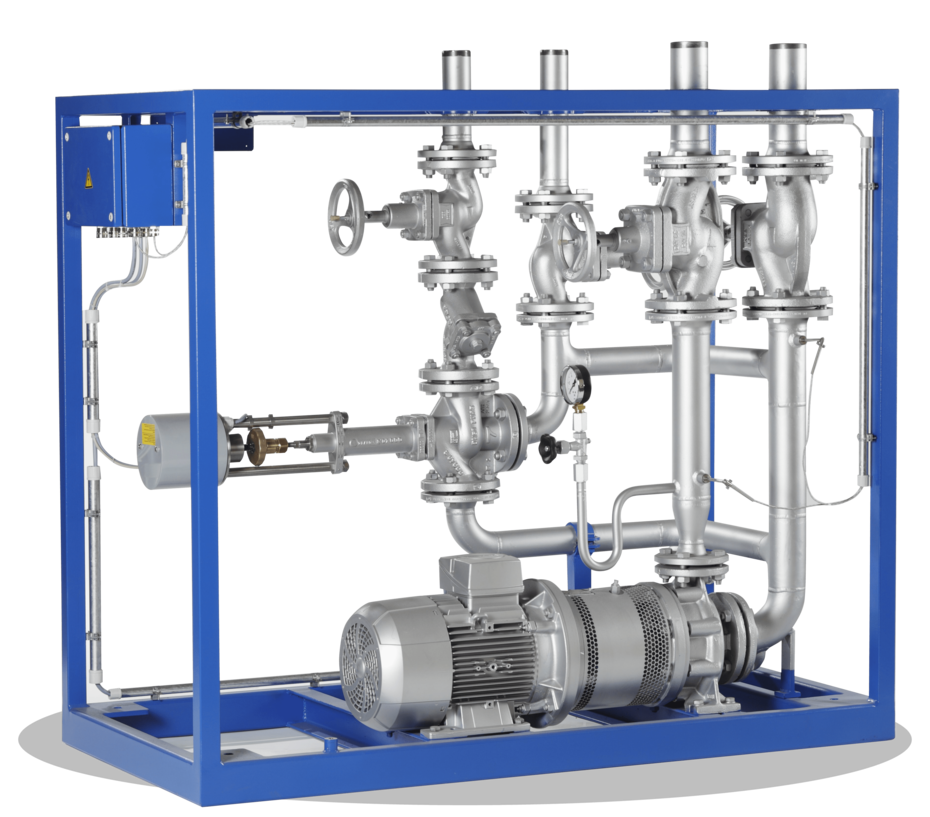

| Combines several smaller consumers efficiently in one system |

|

|

|

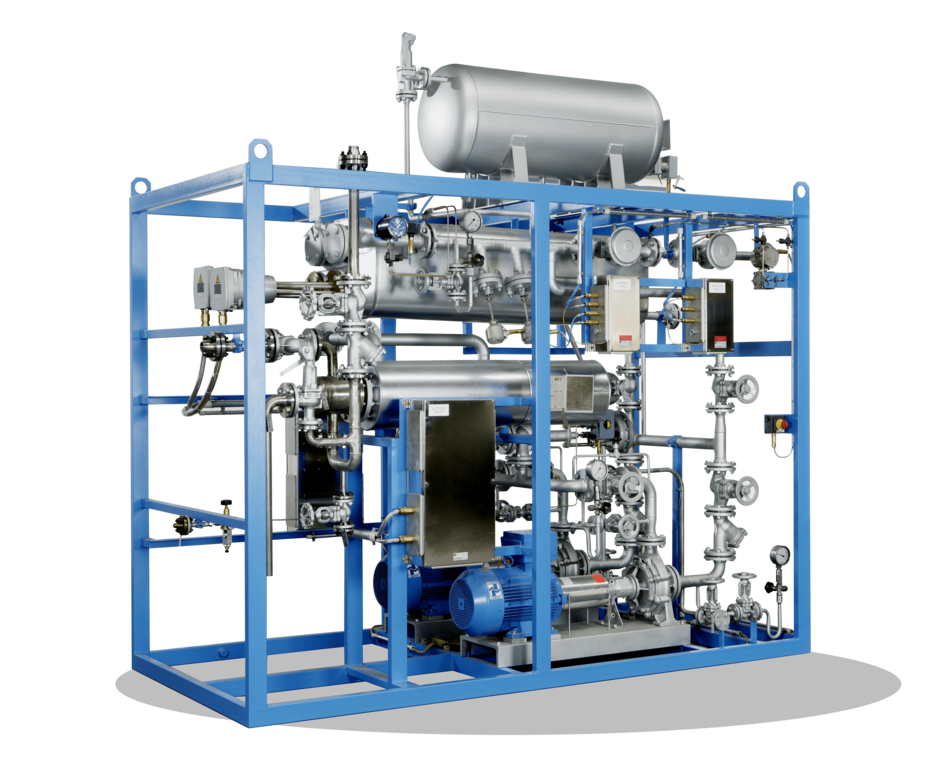

| Heating-cooling systems work with uniform heat transfer media, non-corroding, non-toxic and also food safe (optional). At HTT, this range stands for heating and cooling in the temperature range from -30 °C up to +400 °C. |

|

|

|

|

|

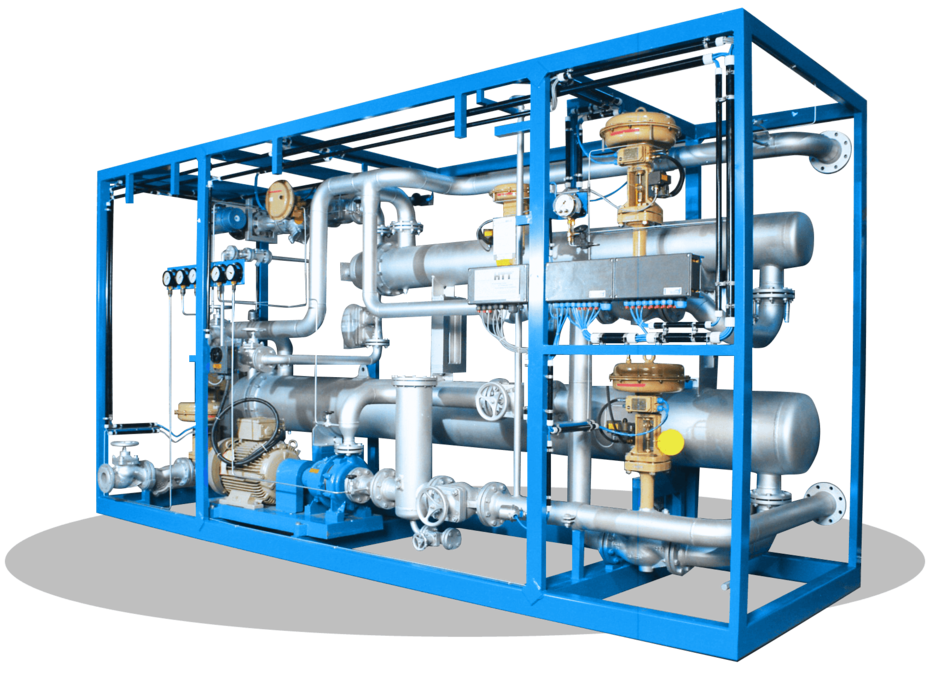

| A further development of established heating-cooling-freezing systems (so-called monofluid systems) is suited for reactor cooling at temperatures of -80°C to -120°C. |

|

|

|